Ship building

Induction heating used throughout the ship building industry is the most effective and environmentally sustainable mechanism. It is used for desk and bulkhead straightening, turbine blade brazing, etc.

Since the inception of water transportation, the shipbuilding industry has flourished. With the creation of mammoth ships and vessels it brought about the transportation of heavy cargo across the globe. The shipbuilding industry has a global footprint and is increasingly becoming competitive.

Building new vessels and refurbishing existing fleets requires advanced technological capabilities, which will excel on the quality front. Compliance with both national and international regulations, environmental concerns and security/safety issues must be considered as well.

Induction heating, used throughout the shipbuilding industry, is recognized as the most effective, reliable, and eco-friendly heating method for a wide variety of processes:

Shipbuilding

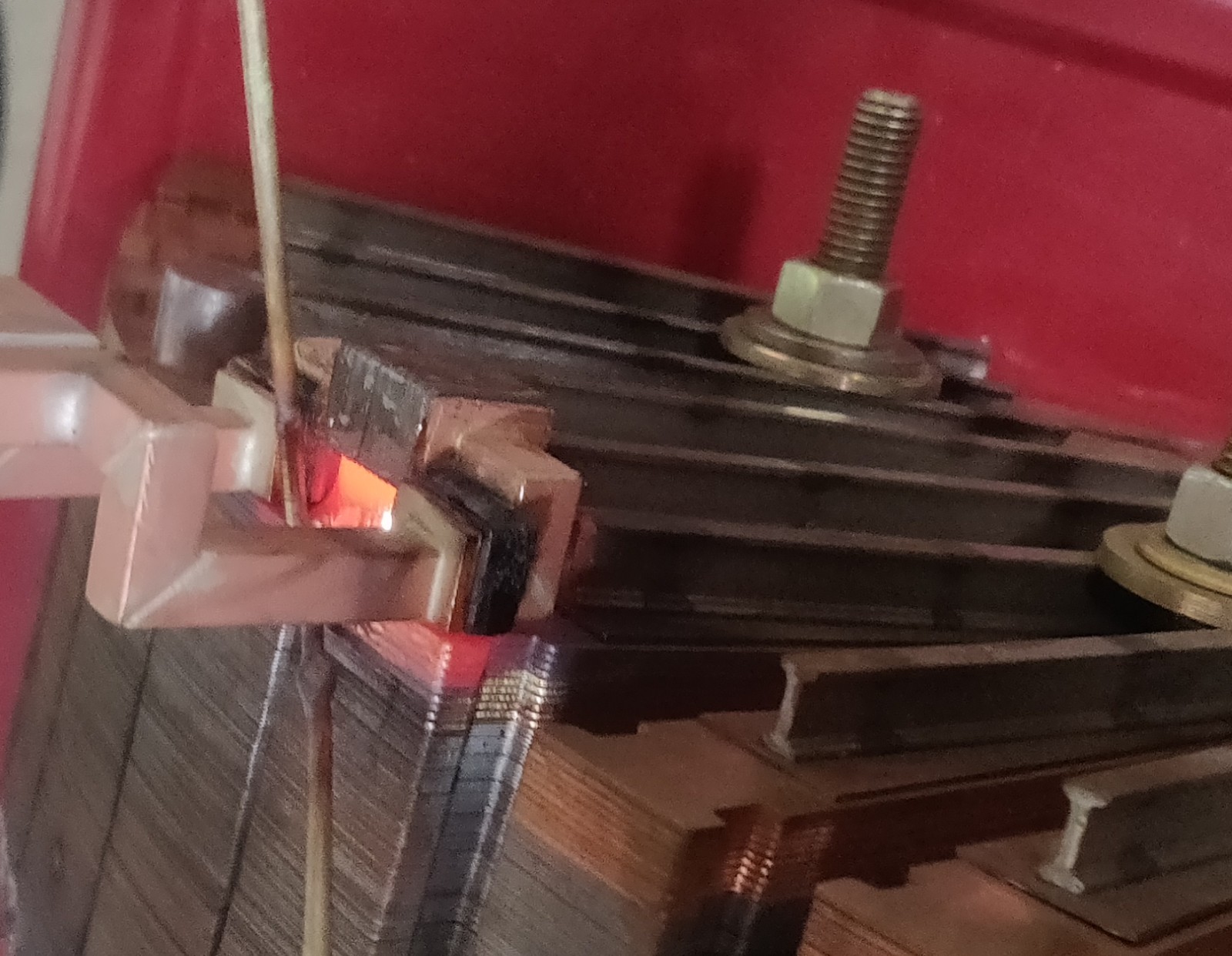

• Deck and bulkhead straightening

• Pipe annealing

• Brazing

• Pre- and post-heating

Repair and maintenance

• Localized metal heating: spot heating, brazing, stress relief, bolt expansion.

• Paint removal.

Engine component heat treating

• Turbine blade brazing

• Gear hardening

• Large bearing hardening

• Shafts and gearbox components heat treating