Railway

Induction heating is used extensively in the railway industry. It is crucial in forging the railroad infrastructure and manufacture of parts for assemblies, bearings, brakes, etc. It has the ability to integrate, streamline and combine multiple process stages.

The railroad was the harbinger of the modern civilization and one of the main engines of modernization. The railway was a catalyst for one of the industrial revolutions. The railways are an integrated public transport system, it connects major cities across the globe. The future of big cities is guided by high-speed rail lines.

The increased globalization of railroads has caused major changes across various parts of the globe. Almost every country in the world has railways.

Induction heating is the heart of the railways. It is widely known for its ease of integration and ability to streamline by combining multiple process stages.

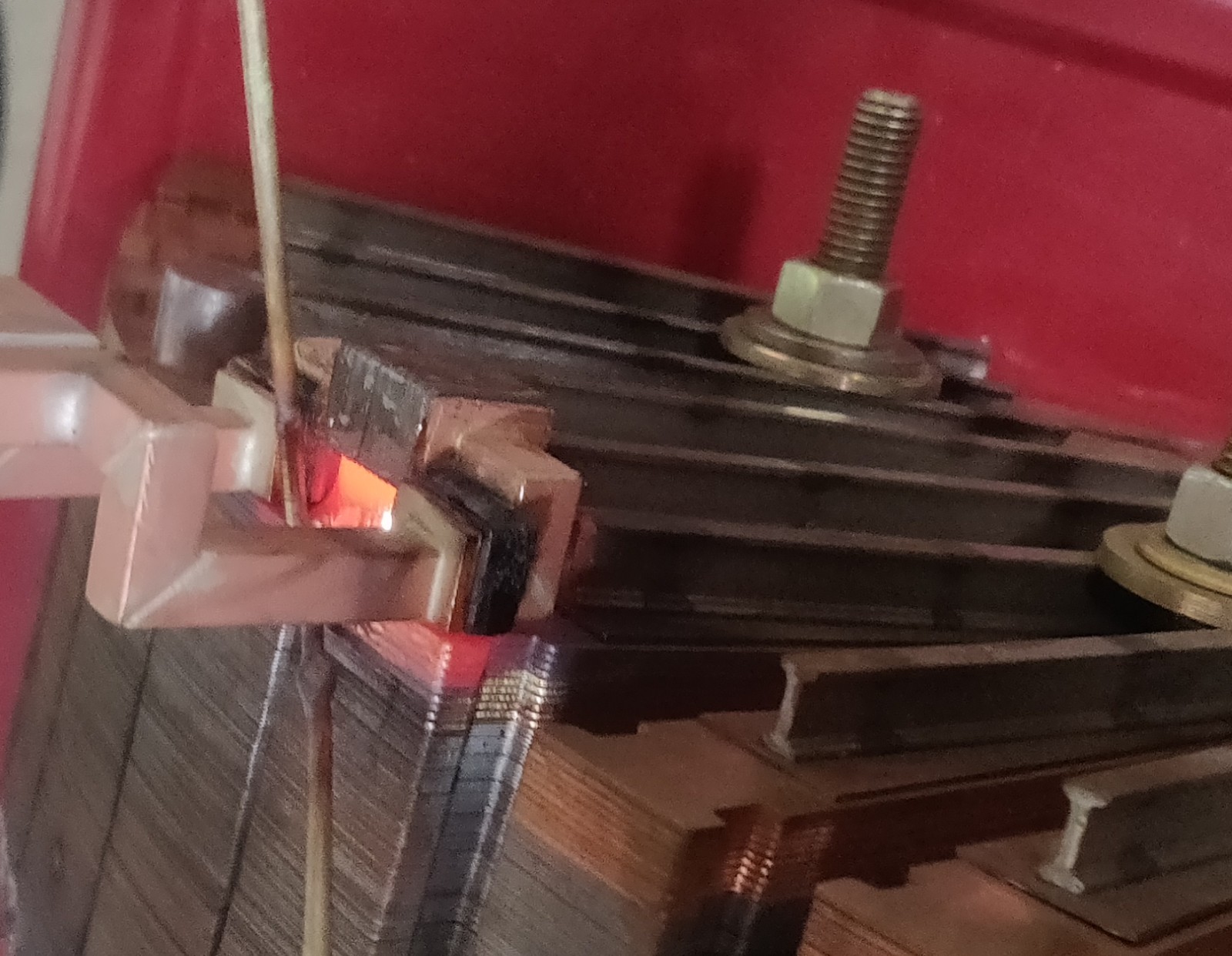

Induction heating is used in every aspect of the railways from the railroad to the trains on the track. Induction hardening is used for manufacturing parts for assemblies, bearings, brakes, drive trains, gears, joints and shafts.

Rolling stock applications

• Diesel motor: parts heat treatment

• Electrical motor: short circuit ring brazing, rotor shrink fitting

• Rail vehicle body: plate straightening, paint removing

• Suspension: leaf spring end heating

• Shaft: molybdenum coating

• Wheelset: wheel shrink fitting

• Brake system: disk brake hardening

Railway maintenance applications

• Motor repairing

• Wheel band shrink fitting

• Spare parts heat treating

Rail infrastructure applications

• Clips forging

• Fasteners thread forging

• Rail forging

• Head rail hardening

• Rail normalizing